The Api 619 Datasheet is a critical document in the world of oil and gas, chemical processing, and other industrial applications involving rotating equipment. This datasheet serves as a standardized form for conveying essential technical information about compressors, ensuring clarity, consistency, and accuracy throughout the procurement, design, and operational phases. Understanding its contents is key to successful project execution.

What is an Api 619 Datasheet and How is it Used?

At its core, the Api 619 Datasheet is a comprehensive questionnaire and specification document developed by the American Petroleum Institute (API). It's designed to detail the requirements for the design, manufacture, and performance of specific types of compressors, most notably process compressors. Think of it as a universal language that engineers, manufacturers, and end-users can all speak when discussing compressor needs. It covers a vast array of parameters, from basic physical dimensions and materials of construction to intricate operational characteristics and safety features.

The Api 619 Datasheet is utilized at various stages of a compressor's lifecycle. During the initial procurement phase, it acts as a basis for vendor quotations, allowing them to accurately price and design equipment to meet the client's specific demands. For engineers, it's an indispensable tool for verifying that a proposed compressor meets all the necessary project specifications and regulatory standards. Operations and maintenance teams rely on it to understand the equipment's capabilities, limitations, and recommended operating conditions, which is crucial for safe and efficient plant operation .

The information captured within an Api 619 Datasheet is extensive. It typically includes sections detailing:

- General Information (e.g., project name, equipment tag number)

- Performance Requirements (e.g., flow rate, discharge pressure, inlet conditions)

- Mechanical Design (e.g., materials of construction, nozzle sizes, weight limitations)

- Driver Information (e.g., type of driver, power requirements)

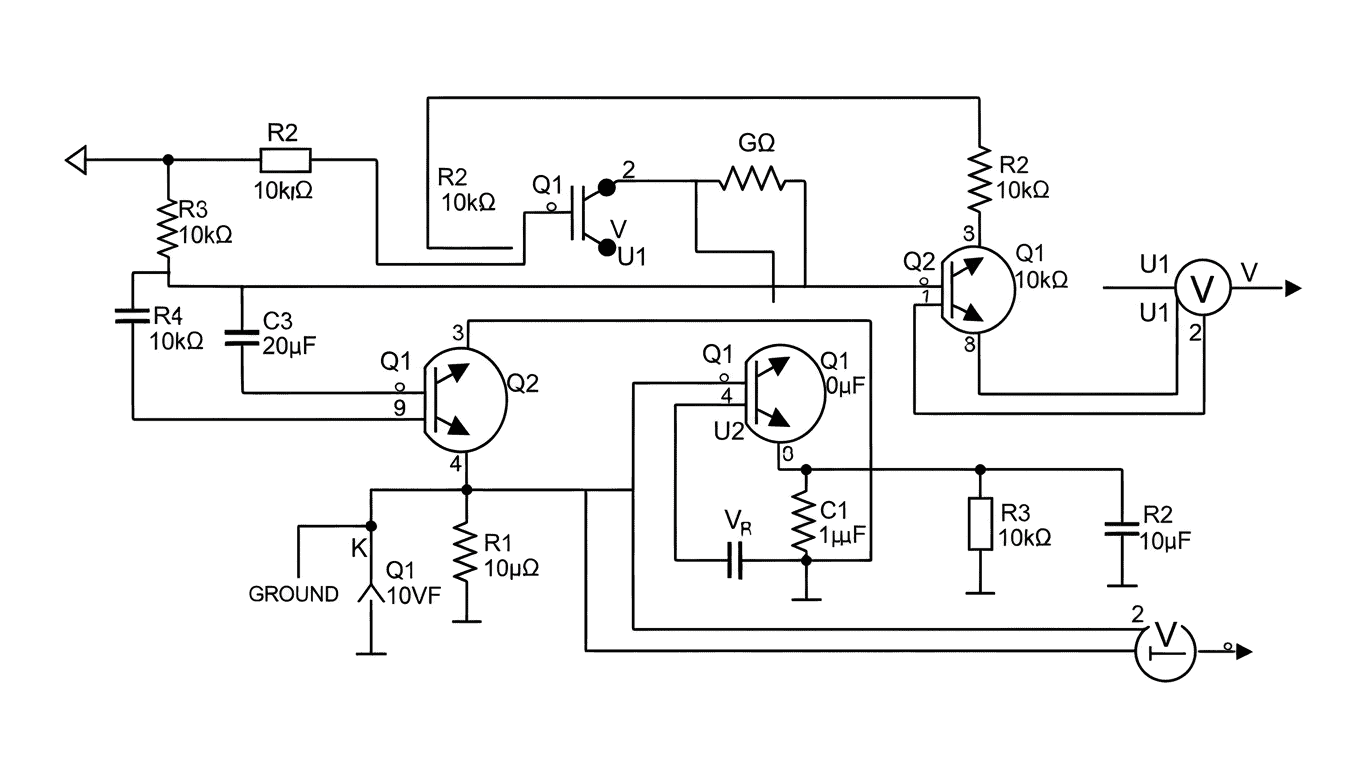

- Instrumentation and Control (e.g., safety systems, monitoring points)

- Testing and Inspection (e.g., performance tests, mechanical run tests)

Here's a simplified look at some key categories:

| Category | Key Parameters |

|---|---|

| Process Conditions | Inlet Pressure, Discharge Pressure, Temperature, Molecular Weight |

| Performance | Flow Rate, Horsepower, Efficiency |

| Materials | Casing Material, Impeller Material, Gasket Material |

By standardizing this information, the Api 619 Datasheet minimizes ambiguity and potential misunderstandings. It ensures that all parties involved have a clear and agreed-upon understanding of the compressor's requirements and expected performance, leading to fewer errors, reduced rework, and ultimately, more reliable equipment.

To gain a deeper understanding of the specific requirements and detailed content of an Api 619 Datasheet, it is highly recommended to consult the official API 619 standard itself. This will provide you with the complete and authoritative information necessary for accurate application and interpretation.